Contents

Steps to correctly prepare a surface when we stick with adhesive tapes

Today we are going to deal with a topic that, although it may seem unimportant to you, is one of the crucial points when it comes to making an adhesive joint. We want to talk to you about how to make a good surface preparation of the materials, before sticking the adhesive tapes, since this will determine, among other factors, the type of union that we will achieve.

And it is that, I tell you right now, that the hours invested in the design of parts, selection and validation of the adhesive tape or liquid adhesive will be of no use, if we do not carry out a correct surface preparation. For this reason, today we want to give you some tips to carry it out properly.

DOWNLOAD TAPE APPLICATION MANUAL

Although there are a large number of methods to prepare surfaces, due to the combinations of adhesives, substrates and factors that interfere with them, we are going to try to synthesize in three, the most frequent procedures to take into account to prepare surfaces when we join with tapes adhesives, especially in the industrial field.

-

Surface cleaning:

The first step consists of eliminating any type of contaminants that are found on the surface of the substrates that we want to join, since their presence causes a decrease in the anchorage of our adhesive.

The cleaning product must be able to eliminate the remains of dirt that the surface may have (dust, salts, oil, etc.) to later evaporate without leaving a trace.

There are several methods of cleaning surfaces and we must choose the one that best suits the type of material. At Fustier we recommend our 3M VHB surface cleaner or if we need to remove adhesive residue, the first thing to do is clean with 3M Industrial Cleaner.

Here is a video so you can see how to do it:

-

Abrasive Treatments:

In some cases, it is necessary to carry out an abrasive treatment before to cleaning, both to remove the surface layer of the material and to generate a larger adhesion surface by creating grooves and irregularities.

There are several methods of abrasion, which can be manual or automatic. We recommend sanding the material with our 3M Scotch Brite 7447, because it erodes the surface without damaging the substrate.

It is important to remember that once the abrasive treatment has been carried out, it will be necessary to clean the surface of residues, contaminants and dust, as indicated in step 1.

Here you can see how to do it:

-

Flamed, Corona Treatment or Primer:

For those cases in which cleaning or sanding the surface is not enough, we can modify the nature of it, through techniques such as flaming, corona treatment or the application of a primer. In the first two cases, what we do is open the pore of the substrate to increase the level of adhesion (especially on plastic surfaces). In the third case, if the application of a primer is necessary, it is important that the surfaces are clean of dust and release agents or oils.

The steps to follow are:

- Apply in ventilated areas, and if necessary, use respiratory protection equipment.

- Apply the primer, applying as thin a layer as possible, avoiding going over the same area several times, as there is a risk of creating layers that could lose cohesion over time.

- Once applied, it must be allowed to dry before applying the tape, approximately 2 to 5 minutes, depending on the porosity of the material and the climate. The important thing is that it is dry to the touch.

- Finally, you must have in mind that you have to apply the adhesive tape, once the primer dries within the next 2-3 hours, since otherwise, the primed surface can be contaminated.

What is the primer applied with?

The best way to apply the primer is with specially designed felt applicators, which also allow our product to be preserved for longer during use, although they can also be applied with a clean and dry brush.

From Fustier we recommend the following elements to apply primer:

- Applicator heads: These can be short or long depending on the needs of each user.

- Regulating filters, to control the flow of primer to be applied.

- Refillable bottle or container that allows you to apply the primer easily and manually.

Here’s how to prepare a surface with primer:

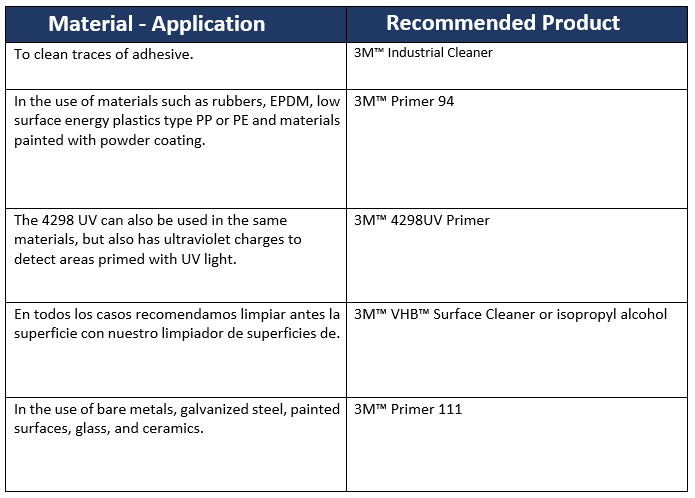

Table with some examples of surfaces, types of contaminants that you can find and the different products and primers that we recommend.

Finally, if you want more information or advice, do not hesitate to write to us through our ONLINE CHAT,

e-mail: [email protected]

FUSTIER IS INNOVATIVE TECHNOLOGY IN ADHESIVE PRODUCTS AT THE SERVICE OF THE INDUSTRY

ANY QUESTION?

We are specialists in the conversion and manufacture of adhesive products at the service of the industry.