Contents

Die-cut films for temporary vehicle protection.

In the automotive industry, the protection of vehicle surfaces and components is essential to guarantee a high level of quality and an impeccable image. In this sense, temporary surface protection films have become an essential solution to guarantee the quality and good condition of the different parts and components of automobiles throughout the production, assembly and transport cycle.

As a distributor and converter of leading brands in surface protection such as NITTO, POLYMASK by PREGIS and TESA, at Fustier we understand the importance of these products in the automotive sector. For this reason, we offer a wide range of high-quality, high-performance films, specifically designed to meet the protection standards of this industry. In addition, our die-cut and customized solutions contribute to saving time, waste and efficiency in the application.

Why are these temporary protection films so important in the automotive industry?

- Protection against damage and scratches: These films protect the surfaces of vehicles and components during assembly, handling and transportation. In an industry where precision is critical, any imperfections can lead to additional costs and production delays.

- Defense against external agents: In addition to physical damage, films also protect surfaces from dust, dirt, humidity, and other factors that could affect the final quality of the product. A relevant aspect especially in components made of sensitive, delicate materials or with specific finishes.

Automotive Temporary Protection Applications:

Some of the common applications that we can find in the protection of parts and components for the manufacture and transport of vehicles are:

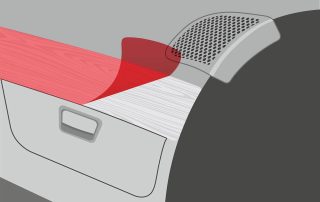

- Protection of interior and exterior surfaces of vehicles during the painting or varnishing process, such as doors, windows, dashboards, seats, panels, screens, fabrics/carpets, upholstery, A- and B-pillars, trim, glove compartments, seats, steering wheels and other interior elements of vehicles, etc.

- Protection of metal, plastic or other material parts that are subjected to manufacturing, assembly, transportation, or storage processes such as: bodies, frames, bumpers, rear-view mirrors, lights, windows, moldings, metal structures, rims and other exterior elements of vehicles.

As we mentioned at the beginning, in the automotive and transportation industry, it is essential to protect vehicle surfaces during the manufacturing and transportation process. However, using conventional materials can be costly and time-consuming to apply or remove. For this reason, at Fustier we recommend using our die-cut solutions, which save time and costs throughout the entire production and transport process, thus guaranteeing the quality of the final products.So, what are the benefits of using our die-cut temporary protection films in automotive and transportation? Below we mention some.

Benefits of die-cut temporary protection films:

- Optimal protection: Our die-cut films are made with the highest quality materials to ensure optimal protection of vehicle surfaces. They are designed to withstand impacts, scratches, dirt, moisture, UV rays, and other damage during the manufacturing and shipping process.

- Perfect fit: Our custom die-cut, pre-cut and centering solutions adapt perfectly to the different surface shapes and sizes of vehicle parts and parts, ensuring complete coverage, fast and efficient application with optimal protection. It also prevents material waste, which in turn reduces costs.

- Ease of application and removal: Our die-cut films are designed for easy application and removal, leaving no sticky residue or damage to vehicle surfaces. This saves time and effort in the process of cleaning and preparing the vehicles for the next stage.

- 4 Colors Available: White, specially designed to protect from UV rays and outdoor environmental conditions. Translucent transparent, blue and green, which allow visual inspection of the product without having to remove the protection.

In the following video we will show you an example of the manufacture and application of a die-cut film with pre-cuts and centering devices.

In summary, our die-cut temporary protection films offer a reliable, efficient, and high-quality solution to protect parts and components in the automotive industry during the manufacturing and transportation process, as they guarantee the quality and good condition of products at all stages.

At Fustier, IATF 16949 certified, as experts in the conversion of temporary protection films, we have a highly specialized technical team that can advise on the choice of the most suitable film for each type of surface and application, thus ensuring optimal and effective protection in an industry that remains in constant evolution and with demanding quality standards.

For more information or advice about these products, do not hesitate to write to us through the form

Our e-mail: service@fustier.es

FUSTIER IS INNOVATIVE TECHNOLOGY IN ADHESIVE PRODUCTS AT THE SERVICE OF THE INDUSTRY

ANY QUESTION?

We are specialists in the conversion and manufacture of adhesive products at the service of the industry.