Hello everyone,

At Fustier we boast a long track record with companies in the railway industry and their different applications. Thus, today we would like to share with you a solution for laying floorings in trains that we consider successful, due to its easy implementation and the multiple benefits it provides, which we can use in other sectors, such as buses, lifts, etc. …

Usually, when we work on projects, such as gluing floors in trains, we have been asked questions such as:

- How can Ireduce the drying time of classic adhesives in order to continue working ?

- How can I reduce the drying time of classic adhesives in order to continue working?

- How canI remove solvents and the odours that come with using them?

Therefore, today we would like to tell you what we usually recommend to use in applications like this: Custom-made self-adhesive flooring, which in addition to solving problems, such as those we have mentioned above, will provide you with other great benefits and advantages in your process.

The steps to carry out this solution will vary in one or two, depending on your needs, and are as follows:

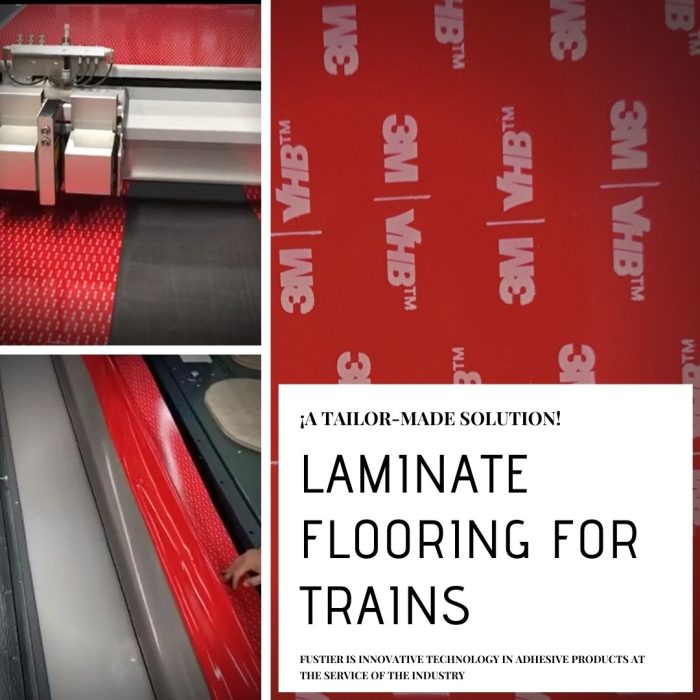

Laminating the Flooring

In this step, we use large-format laminators. Here the process consists of pre-adhesive laminating your flooring with one of our 3M VHB double-sided tapes, which have been previously specified for the application, and we turn it into a self-adhesive flooring, with all the advantages that this provides (easy application, easily removable liner, cleanliness when gluing, etc.)

Cutting the Flooring to Measure

The next step is to cut the laminated flooring according to the shape and measurements specified in the client’s drawings. This provides agility and precision in gluing the flooring to the substrate, thus helping to optimise process times.

In short, self-adhesive laminate flooring is an adhesive solution that provides the following benefits:

- No odours or solvents, hence eliminating the use of respiratory protection

- It complies with the European Fire and Smoke regulation EN45545 for trains.

- It provides greater sound and heat insulation, thanks to our 3M VHB double-sided tapes.

- It reduces drying and preparation times, as the laminate flooring adheres immediately, and you can continue working on it.

- It is cut to the client’s needs and adapted to the size of the rolls to optimise material.

- Provides improved floor maintenance processes, as the VHB tapes ensure cohesive breakage and can be replaced without damaging the train substrates.

Finally, please find a short video below, where you can see a case study of flooring lamination and cutting for the bathroom floor of an actual train.

https://youtu.be/of2RrrwgRm0

As usual, if you would like more information or advice, do not hesitate to write to us via our ONLINE CHAT

e-mail: [email protected]

FUSTIER MEANS INNOVATIVE TECHNOLOGY IN ADHESIVE PRODUCTS TO SERVE THE INDUSTRY

ANY QUESTION?

We are specialists in the conversion and manufacture of adhesive products at the service of the industry.