Since the start of the COVID-19 pandemic proper signalling and marking of floors has become more important to make work safer for everyone. Among other things, it helps us to maintain the recommended safety distance (a highly topical issue nowadays), as well as giving us clear indications about the areas that must be cleared in our facilities, reducing the risk of possible accidents and promoting protection of both company personnel and our clients and suppliers.

Contents

How can I properly signal and mark floors?

To answer you, although there are many guidelines to do it, today we are going to give you only5 tips for properly marking floors in times of Covid-19; then, we will mention 5 marking tapes that can help you to achieve it thanks to their versatility and durability.

Below you will find the 5 tips:

Take into account the regulatory framework and current legislation

First of all, we must take into account the current legislation. Given that there is currently an exceptional risk of contagion from COVID-19, guaranteeing a safety distance of two metres, as well as minimising contact between workers, customers and suppliers is one of the new recommendations within the current regulatory framework; we should therefore review the latest version and use it to adapt our spaces to this legislation. We also recommend you include quality management techniques, such as the 5 S, which is one of the best-known and used nowadays.

Here you can download the new regulatory framework:INSST COVID-19 Regulatory Framework.

Assessing risks and planning correctly

It is necessary to assess the risks within our facilities to plan both the storage areas, passageways or corridors and the work and storage areas. To do this, it is important to make the correct safety signs visible and clear to everyone. Hence the importance of taking the colour code into account.

Taking the colour code into account

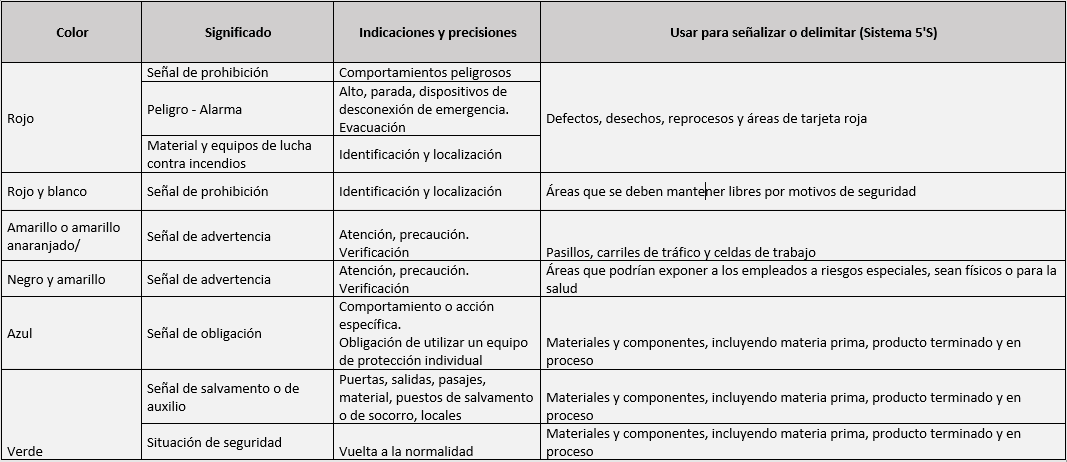

To mark and signal correctly, it is necessary to know the colour code and adhere to Royal Decree 485/1997 of 14 April (BOE [Official State Gazette] 23/IV/97) on minimum provisions regarding Health and Safety Signage at Work, which states the following regarding safety colours and their use. (see table below)

Planning maintenance

Once we have marked and signalled our facilities, it is common for us to forget that periodic maintenance is necessary, since, if there are deteriorated areas or whose marks are not visible, they may not be respected or complied with. Let us remember that the behaviour of our workers, suppliers or customers will depend on a correct, visible and well-maintained signage. Hence, periodic reviews are essential to keep the marking of the facilities in perfect condition and everything flowing correctly.

Staff training

Another point we would like to mention, although it may seem obvious, is the need to train our workers in signalling and marking the facilities, as this will guarantee their correct use and compliance.

Which 3M adhesive tapes should I use for signalling and marking floors?

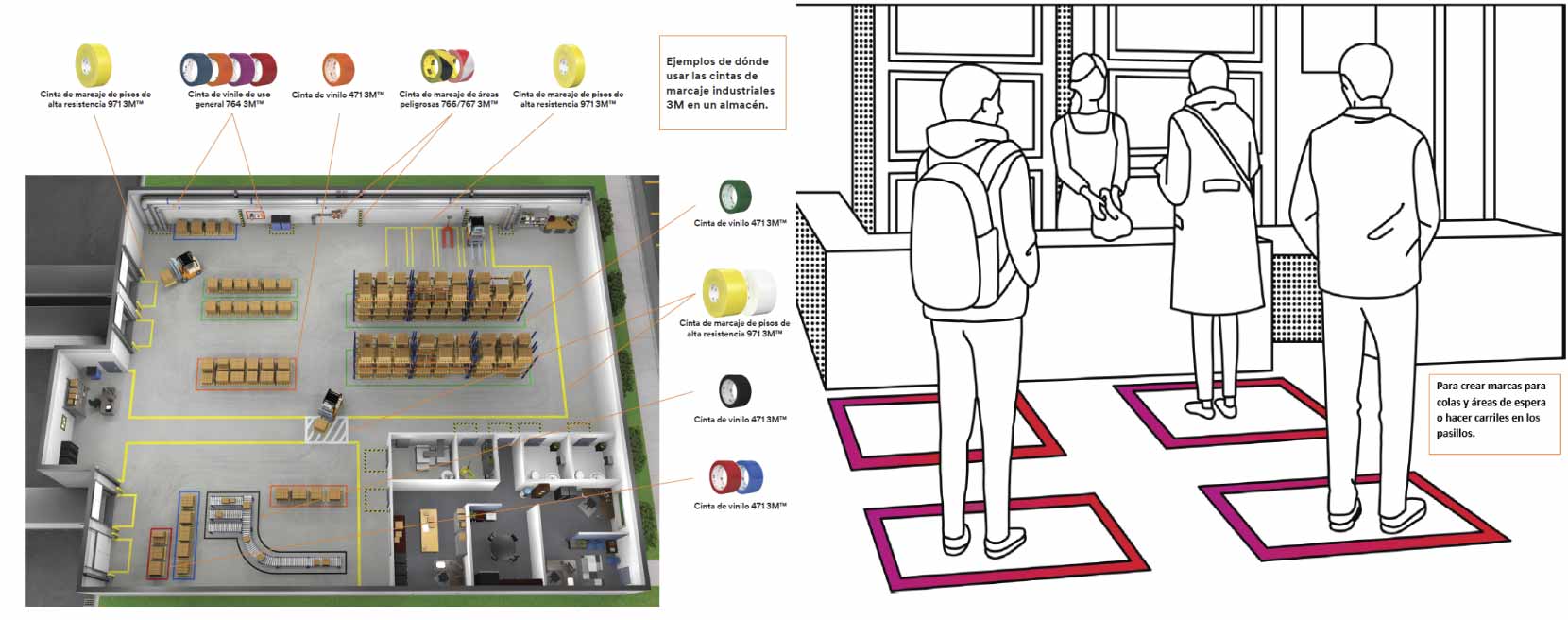

Finally, as we mentioned at the beginning of this post, at Fustier we have 5 3M floor marking products that can help you mark your facilities, as well as create social distancing marks in a fast, easy and efficient way, maximising the workflow, overall safety and appearance of your factories and warehouses.

Here are our recommendations for 3M adhesive tapes:

- 3M 471: Quick removal and residue-free floor marking tape

- 3M 764: Temporary floor marking tape

- 3M 971: Floor marking tape with high resistance to abrasion and chemicals

- 3M 766/767: Ideal for marking applications in hazardous areas

- 3M 5702: Ideal for marking applications in hazardous areas requiring chemical or solvent resistance

Finally, here is a video where you can see how to use the different 3M marking tapes.

Please do not forget that, if you would like more information or advice, you can write to us via our ONLINE CHAT,

e-mail: [email protected]

or call us at ![]() +34 934 600 479

+34 934 600 479

FUSTIER MEANS INNOVATIVE TECHNOLOGY IN ADHESIVE PRODUCTS TO SERVE THE INDUSTRY

ANY QUESTION?

We are specialists in the conversion and manufacture of adhesive products at the service of the industry.