Contents

Reduce, Reuse, Recycle: How Tapes and Adhesives Drive Sustainability in Manufacturing

In a world increasingly aware of environmental impact, sustainability has become a determining factor for the success of any company. The manufacturing industry is no exception, and more and more solutions are being sought to reduce the environmental impact of production processes and final products. In this context, tapes and adhesives are positioned as strategic allies, offering innovative and efficient solutions to improve the quality, safety, ergonomics, design and durability of products, while minimizing the consumption of resources and the generation of waste.

How can tapes and adhesives contribute to more sustainable manufacturing?

Tapes and adhesives can contribute to sustainability in manufacturing in a variety of ways, including:

-

Reduction of material consumption and waste generation

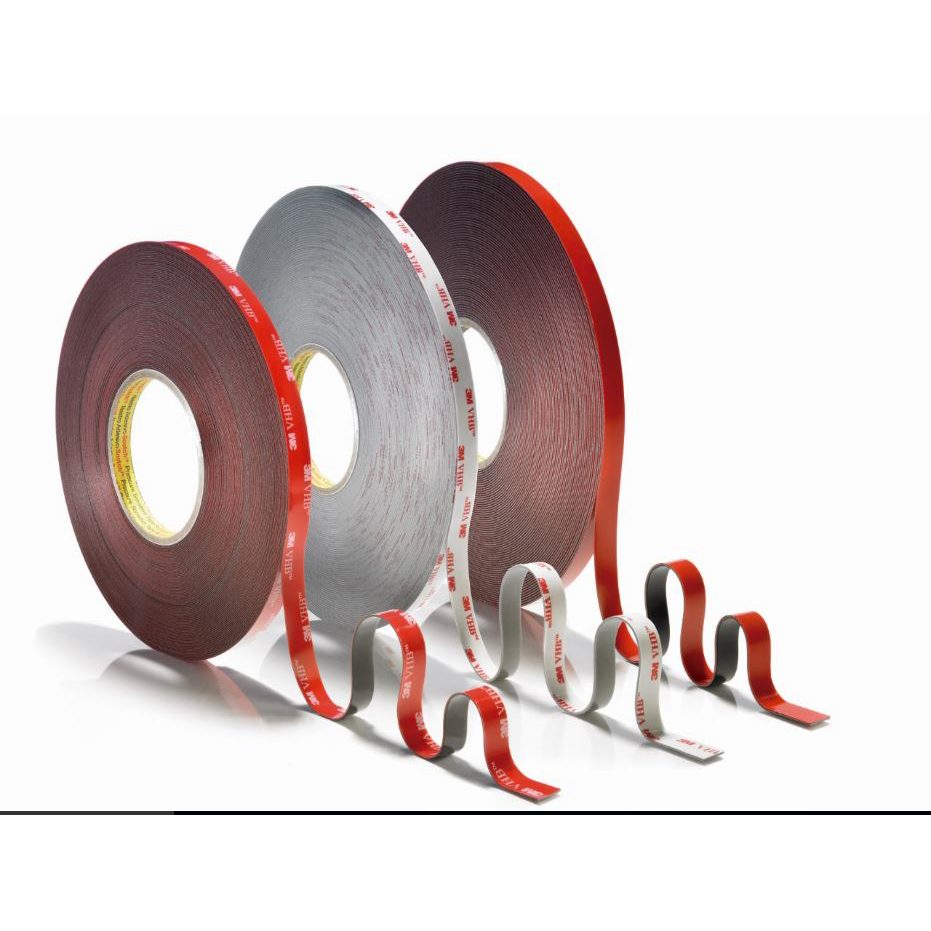

In the industrial manufacturing of products such as appliances, wearables, electronic devices, etc., tapes and adhesives allow for the use of lighter, more recyclable materials, as well as greater flexibility in designs. Which translates into a reduction in the weight and volume of the final products. This facilitates its transportation, storage and reduces associated CO2 emissions.

In sectors such as the automotive, transport and railways, its use contributes to the manufacture of lighter, more efficient vehicles that consume less fuel and are consequently less polluting, meeting standards of the industry that increasingly demands sustainable transportation.

- Greater efficiency and product quality

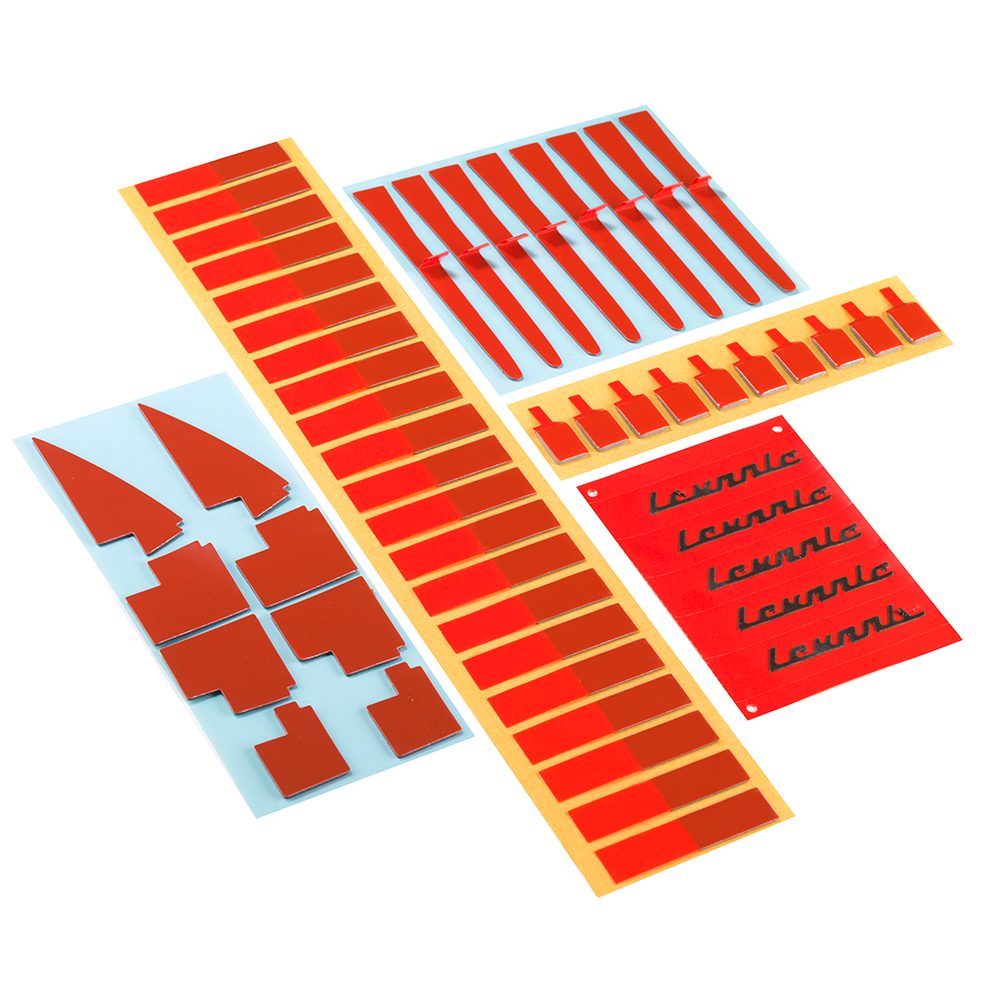

Tapes and adhesives provide a strong and durable bond, in many cases replacing screws, rivets or other mechanical elements that can damage materials or create weak points. Additionally, the use of die-cut adhesive tapes and adhesives improve accuracy in the application of materials, reducing waste and energy consumption in grinding processes.

- Facilitate the reuse and recycling of components

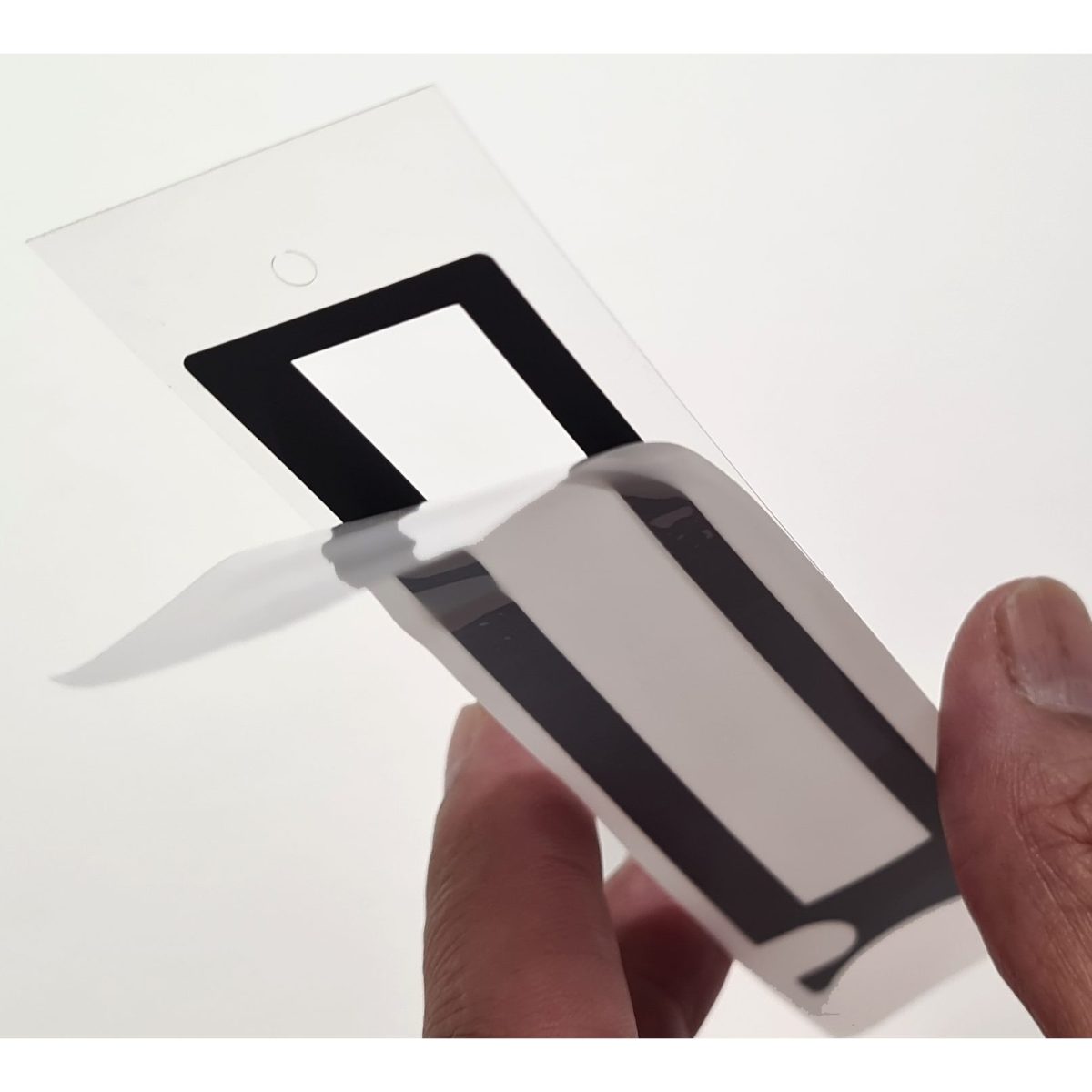

There are tapes and adhesives designed to create structural and durable joints. However, it is important to clarify that there are several types of tapes and adhesives with specific properties that facilitate the disassembly of components and products, allowing their reuse or recycling.

Tapes and adhesives that improve designs and user experience

-

Automation and digitalization of production processes

Adhesive tapes and adhesives in many cases and applications facilitate the automation and digitalization of production processes, which increases productivity, quality and traceability of products, reducing operating costs and human error.

Automation with tapes and adhesives

-

Compliance with safety regulations

Adhesive tapes and adhesives comply with the most demanding safety regulations, which guarantees compliance with quality standards of sectors such as: automotive, pharmaceutical, electronics, aeronautical, railway, etc.

-

Sustainable tapes and adhesives.

In addition to the advantages mentioned above, there are tapes and adhesives on the market with a positive impact on the environment thanks to their composition:

- Biodegradable tapes or tapes made from recycled material for packaging: These are tapes that decompose into natural elements or are recycled, without leaving toxic waste or contaminating the environment.

- Water-based adhesives: These are adhesives that do not contain solvents or volatile organic compounds (VOCs) that may affect people’s health or the environment.

- Hot melt adhesives: Activated by heat and solidify when cooled, allowing efficient use of the material without wasting energy or generating waste.

- Solventless tapes: These are tapes that are manufactured without solvents, which reduces their environmental impact and improves application safety for workers.

-

What is the common objection to sustainability in manufacturing with tapes and adhesives?

A common objection is the perception that tapes and adhesives are more expensive. However, the reality is that they can generate savings in the medium and long term. Tapes and adhesives help optimize and simplify designs, reducing the number of parts and components in final products, which not only makes products lighter, but also reduces the energy required for their manufacturing and assembly. Fewer parts mean more efficient use of resources and less waste generation.

In short, tapes and adhesives are a fundamental part of the sustainable manufacturing of the future, since they contribute to the use of more efficient materials, reduce waste and optimize production processes.

If you want to know more about how tapes and adhesives can help you improve your production process and your final product, do not hesitate to contact us, we will be happy to advise you.

You can write to us through the contact form, our e-mail: [email protected]

FUSTIER IS INNOVATIVE TECHNOLOGY IN ADHESIVE PRODUCTS AT THE SERVICE OF THE INDUSTRY

ANY QUESTION?

We are specialists in the conversion and manufacture of adhesive products at the service of the industry.