Contents

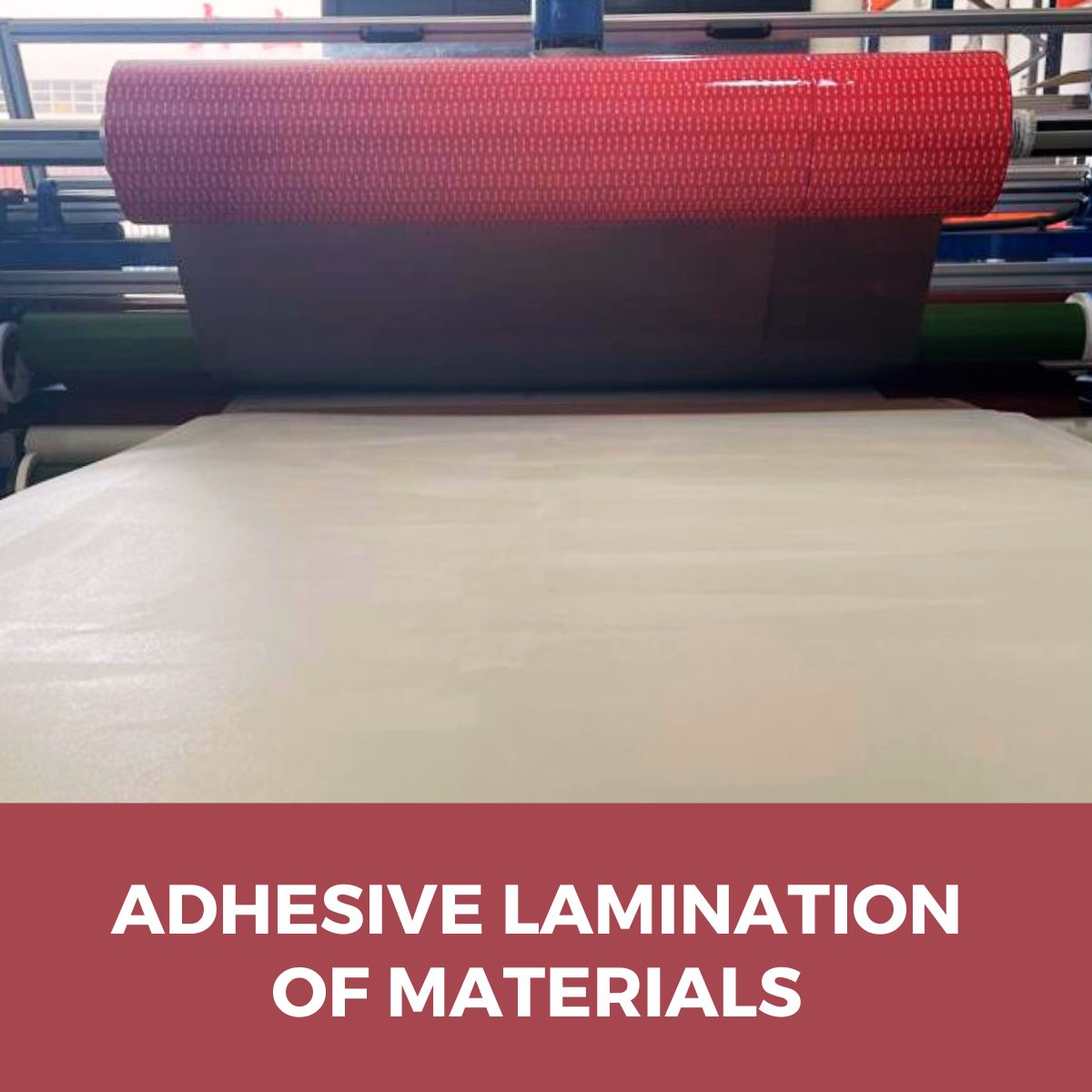

Lighter, stronger, faster: laminating your materials with adhesive makes it possible.

Adhesive lamination to make self-adhesive materials has become an innovative and efficient solution for various bonding applications, offering benefits such as facilitating the installation of large parts and helping to improve the overall performance of some products. At Fustier, with more than 40 years of experience as converters, we are experts in the conversion and adhesive lamination of a wide range of materials, including flooring, flooring, foams, felts, HPL, panels, among others.

What is adhesive laminate and why do we recommend it?

Adhesive lamination consists of pre-adhesive laminating one or more materials, making them self-adhesive for different types of applications. In some cases, the aim is to optimize the production processes of the installation, laminating with a high performance adhesive, and in others, to create a new product with properties superior to those of the original materials. In any of the cases, there are multiple benefits. Here are some of them.

Key benefits of adhesive laminate

- Ease of InstallationAdhesive lamination facilitates quick and easy installation of large parts, without the need for highly qualified personnel. It is a solution that simplifies processes and reduces assembly times.

- Weight Reduction: : By dispensing with mechanical fasteners, laminated materials are often lighter than conventional solutions, resulting in a significant decrease in the overall weight of structures, which is crucial in certain applications.

- Noise and Vibration ReductionThe use of adhesive materials such as 3M VHB acrylic foams and similar in the laminate helps to significantly absorb vibrations and noise in bonding applications for vehicles, trains or elevators, thus improving the comfort and quality of the indoor environment.

- Improved Mechanical StrengthThe combination of different materials in the lamination process can result in higher resistance to tensile, bending and other mechanical stresses, increasing the durability and service life of the products.

- Heat DissipationSome adhesive laminate materials are designed to improve heat dissipation, which is crucial in electronic and high temperature applications. This helps keep components at optimum temperatures, extending their service life.

- Cut to SizeAt Fustier, we offer the ability to cut to size the laminated pieces, facilitating even more their installation and adaptability to the specific needs of each project.

Other advantages of adhesive laminate

- No odors or harmful gases: Replacement of solvent-based adhesives with laminated adhesive materials, which do not emit odors or toxic fumes, creating a safer and healthier work environment.

- Simplification of processes: The use of laminated adhesive materials simplifies production processes, eliminating complex mechanical fasteners, reducing the time and effort required for installation and handling.

- Cost reduction: As a result of optimization in the use of materials and the need for fewer qualified personnel.

- Waste reduction: Precision cutting and application of laminated materials minimizes waste during the manufacturing and installation process, contributing to more sustainable production.

- Elimination of grinding, polishing and cleaning: Laminated adhesive materials require no additional finishing work, saving time and resources.

- Simple removal and easy replacement: When parts need to be replaced, the laminated adhesive materials can be easily removed without damaging the underlying surfaces.

- No bubbles or wrinkles: The application of laminated adhesive materials prevents the formation of bubbles and wrinkles, ensuring a perfect finish.

Common applications of adhesive lamination of materials

The possibilities for adhesive lamination of materials are virtually unlimited. Some of the most common applications include:

- Railway sector: sandwich panels, hpl and honeycomb laminate, flooring, acoustic and thermal insulation.

- Construction, Architecture and Interior Design sector: facades, floor, wall, ceiling, paneling, furniture.

- Automotive industry: interior linings, instrument panels, acoustic and thermal insulation.

- Elevator industry: panels and floors.

At Fustier, we are committed to innovation and quality, offering adhesive laminating solutions that meet the highest industry standards. Our expertise and ability to customize laminated parts allow us to meet the specific needs of our customers, providing products that improve the efficiency and performance of their applications.

If you need more information, do not hesitate to contact us through the form below the e-mail: [email protected]

We are at your disposal to advise you and help you find the best solution for your project.

FUSTIER MEANS INNOVATIVE TECHNOLOGY IN ADHESIVE PRODUCTS TO SERVE THE INDUSTRY

¿ANY QUESTIONS?

We are specialists in converting and manufacturing adhesive products at the service of the industry.