Lighter, safer and more efficient trains, here is how to do it

Today, I would like to talk to you about specific adhesive solutions for the railway and bus sector, which can help you adapt your manufacturing to new market trends. Trends that are largely the result ofthe goals set by the EU for 2050 towards more effective and efficient transportation, hence their relevance and the need to adapt quickly to them.

- Lighter vehicles for greater energy efficiency and less pollutants

- Increased use of environmentally friendly and composite materials in manufacturing

- Designs that provide an enhanced passenger experience

- Greater competition with other means of transport, e.g. cars and airplanes

They are some of them, in which structural adhesives and adhesive tapes play an important role.

At Fustier, in coordination with 3M™, we have been working on adhesive solutions that help manufacturers meet these challenges in their design and production processes in order to help them adapt to new trends. Below you will find some successful solutions that you can implement with our 3M™ products.

How to make vehicle structures lighter

Below you will find some solutions that will make your vehicles lighter, with composite and environmentally-friendly materials, which help to create designs that improve the passenger experience by helping to reduce vibrations and noise, as well as making them competitive with regard to other means of transportation, such as cars or airplanes. So, without further ado:

-

Solution 1: Composite Materials + Structural Adhesives

A successful and proven solution from Fustier is to replace metals with composites or polymers and use 3M™ structural adhesives to replace welds, as they provide great additional benefits such as uniform load distribution over the surface of the joint area, which reduces the potential for fatigue damage, extends joint and product life and dramatically reduces replacement or repair costs. For example, using 3M™ structural adhesives on a composite or honeycomb floor panel has a major impact on reducing the weight of a train or bus floor structure:

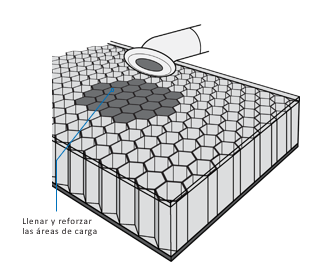

Example of application of 3M7240 on honeycomb composite panel to increase span distance and decrease weight in a vehicle structure

Thus, at a veryhigh module, say (3,500 – 4,000 MPa) + our 3M SW7240B/A FR structural adhesive, we significantly increase the panel strength and reduce the need for stiffeners and support bars, hence reducing the overall weight of the structure, e.g. (Table)

-

Solution 2:Filling and reinforcing the panel core with3M™ Scotch-Weld™ Adhesives

To continue with alternatives that allow you to build lighter, stronger, less labour-intensive and environmentally-friendly structures, I would like to mention the following solution, which has been successfully used in other industries, such as aerospace, and can be replicated in all those applications where honeycomb is used. It consists of filling and reinforcing the core of the honeycomb panels with our specifically designed3M™ Scotch-Weld™products. This is a low-density solution that reduces the weight of vehicle furniture, provides a moisture barrier and acts as a vibration dampener. It also improves application efficiency due to its fast cure time at room temperature, whereas its thixotropic properties provide a controlled, self-levelling flow.

-

Solution 3: using3M VHB™, Dual Lock™ and Extreme Sealing Tapes

Finally, I will mention another successful and proven solution from Fustier to reduce weight in the vehicle structure, which is to use 3MVHB™, Dual Lock™ and Extreme Sealing Tapes, thus helping to reduce weight compared to traditional 1K PU sealants. Below you can see an example of a real case.

Table and examples of weight reduction by replacing traditional sealants with Dual Lock and sealing tapes

These are some of the solutions that we at Fustier as 3M™ preferred dealers and converters can provide you with so that your manufacturing is in line with market trends.

If you would like more information or advice, do not hesitate to write to us via our ONLINE CHAT,

e-mail: [email protected]

FUSTIER MEANS INNOVATIVE TECHNOLOGY IN ADHESIVE PRODUCTS TO SERVE THE INDUSTRY

ANY QUESTION?

We are specialists in the conversion and manufacture of adhesive products at the service of the industry.