As we already know, the strong competitiveness of the market forces companies to adapt and be flexible, including continuous improvement processes to offer the best quality in their products.

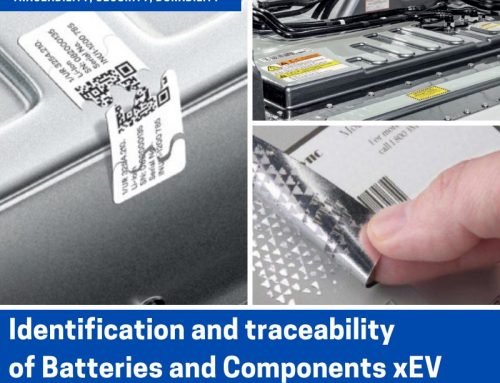

In this sense, traceability within the production system is a matter of utmost importance, since among other things, it helps to control the entire useful life of any part, saves time in assembly processes and also helps to detect defects in the chain manufacturing of the product.

In today’s blog we want to talk to you about a recurring theme in some clients, which is the IDENTIFICATION AND UNIT TRACEABILITY OF THE PIECES BEFORE THE ELECTROCOATING PROCESS, as well as a solution with which the Fustier Group has been successful and that may interest you, without delving into the process, because, it is not the objective of this article, but rather that you know the benefits they can provide you.

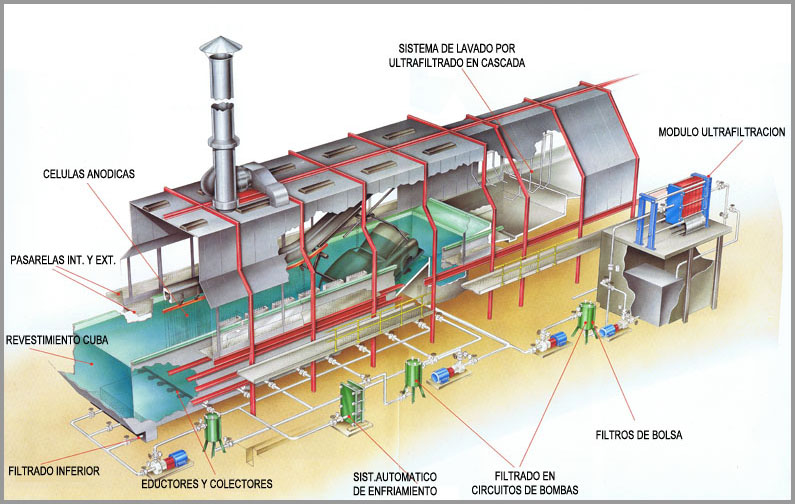

For those who do not know what electrocoating process is, and in a generic way, it consists of a process in which metal parts are subjected to a series of steps to turn them into corrosion-resistant parts.

The pieces are previously identified, however, once they go through the electrocoating process, they can generate problems with their identification and traceability, because the steps are aggressive for traditional label materials.

This is where our 3M labels are an EXCELLENT SOLUTION FOR IDENTIFYING AND TRACING the metal parts that undergo this process.

To continue, we will tell you its main characteristics, the benefits they can bring you, and we will mention some of the common applications in which they can be used.

FEATURES of 3M Labels:

- Resistance to high temperatures.

- Resistance to degreasers and solvents.

- Legible printing and coding throughout the process.

- High adhesion power on surfaces contaminated with oil.

- No electrical conductivity.

BENEFITS of 3M Labels:

- It resists the entire electrocoating process, due to its greater adhesion power and greater durability of the labels.

- As the label does not conduct electricity, the paint is perimeter adjusted to it, leaving no space where corrosion can enter.

- The print is resistant to various chemical agents.

- Possibility of applying automatically on the piece (to be studied case by case).

- Greater control and traceability of production by identifying post stamping of metal parts.

To continue, we will mention common traceability applications of some customers in the automotive sector:

AUTOMOTIVE APPLICATIONS:

- Battery Housing or Battery Pack.

- Structure and parts of seats.

- Components and modules for chassis, body, engine and exhaust systems.

- Spare wheel holders

- Protectors and components of the braking system.

Finally, we remind you that our commercial technical department will give you all the necessary assistance to design and develop the adhesive solution that makes it easier to implement within your production process.

So if you need more information or advice, you can ask your COMMERCIAL TECHNICAL ADVISOR about these products

write us through our ONLINE CHAT,

e-mail: [email protected]

FUSTIER IS INNOVATIVE TECHNOLOGY IN ADHESIVE PRODUCTS AT SERVICE OF THE INDUSTRY

ANY QUESTION?

We are specialists in the conversion and manufacture of adhesive products at the service of the industry.