Contents

Do you know how to check if the thickness of your adhesive tape is adequate? We show you how to test it with a wet-out test!

In the world of adhesion, not all tapes are the same. The thickness of the adhesive tape plays a key role in its performance and bonding capacity. Choosing the correct thickness is crucial to ensure strong, durable and effective adhesion.

To ensure that you are using the correct tape thickness for your application, we recommend performing a wet-out test. This simple test will allow you to verify it easily and quickly.

How to perform a Wet Out Test?

Just follow these steps:

- CLEAN AND DRY the surfaces to be bonded It is important that surfaces are free of dust, dirt or any other contaminants that may affect adhesion.

- APPLY COLORED INK to the surface of the part including the tape already applied. Be sure to cover the entire surface of the tape evenly.

- JOIN THE PIECES TOGETHER BY APPLYING PRESSURE as you would normally do in the application. Apply firm, even pressure over the entire surface of the tape.

- REMOVE THE PIECE AND IDENTIFY CRITICAL CONTACT AREAS from the wet marks left by the ink on the substrate. Look carefully at the ink marks left on the surface.

How to interpret the results?

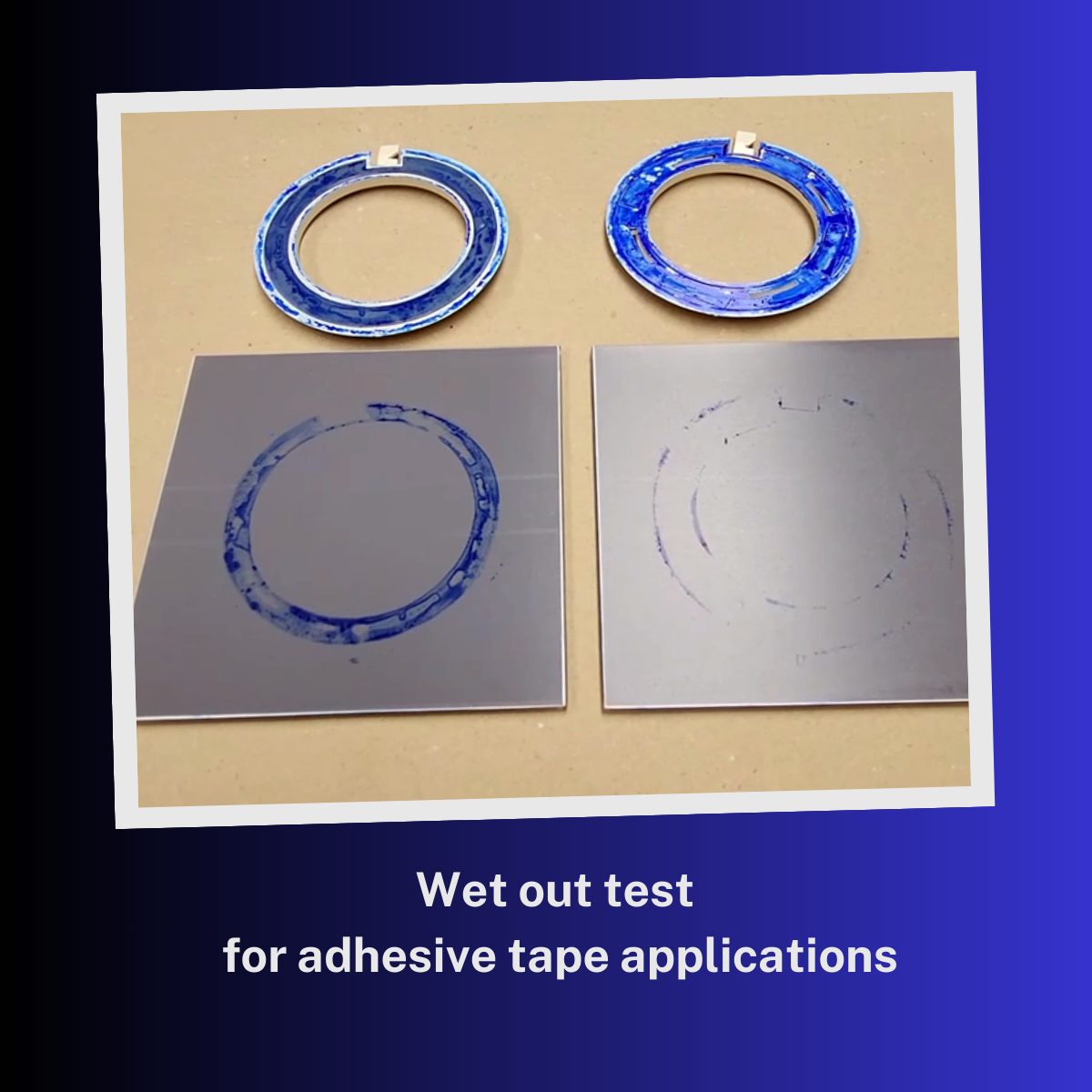

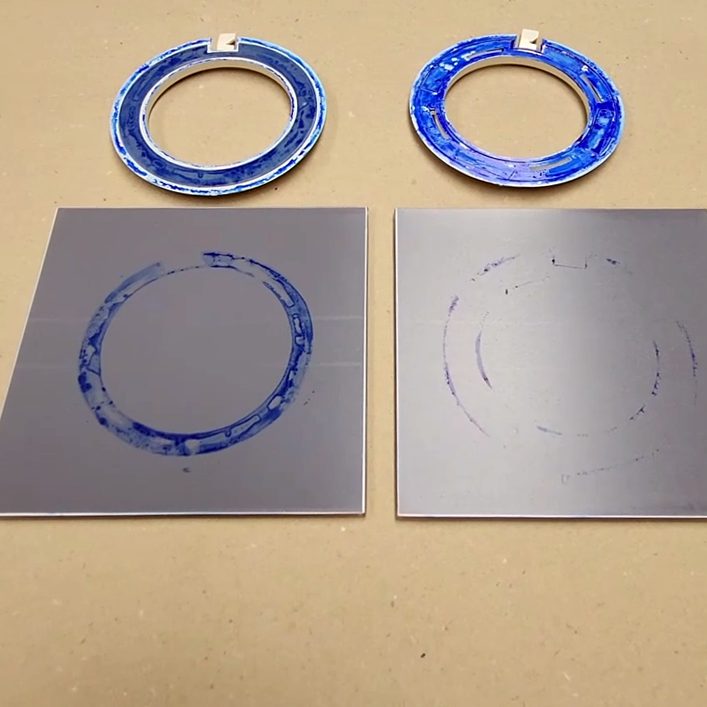

✅ If wet ink marks are visible on more than 90% of the surface. means that the thickness of the tape and the pressure exerted are suitable for the application. The ink has covered most of the surface, indicating that the tape is filling the spaces correctly and good adhesion is occurring between the two surfaces.

❌If wet ink marks are only visible at specific points.If wet ink marks are only visible in specific spots, it means that the tape thickness and/or the pressure exerted are not suitable for the surfaces to be bonded. In this case, the ink has not been able to cover the entire surface, indicating that there are gaps or areas without adhesion.

If this is the case, it is necessary to increase or decrease the thickness of the tape to optimize the application. By increasing the thickness of the tape, the gaps can be filled better and a larger contact surface can be achieved .Additionally, increasing the application pressure will force the tape to adhere better to surfaces.

Remember that performing a Wet-out Test is a simple and effective way to verify if the thickness of your adhesive tape is adequate for your application. The Wet-out Test, also known as Wet Test, allows you to check it easily.

At Fustier, as experts in adhesive solutions, we have a highly specialized technical team that can assist you in choosing the most suitable adhesive tape for each type of surface and application, thus ensuring an optimal and effective bond. Do not hesitate to contact us with your questions! We will be glad to help you

You canwrite to us through the form below

write us to e-mail: [email protected]

FUSTIER MEANS INNOVATIVE TECHNOLOGY IN ADHESIVE PRODUCTS TO SERVE THE INDUSTRY

¿ANY QUESTIONS?

We are specialists in converting and manufacturing adhesive products at the service of the industry.